Pressure Piling

You may have heard of the phenomenon called “pressure piling”, which adds to the severity of an explosion. In this animation, we’re going to talk about pressure piling, which can happen when explosion proof enclosures are not designed and installed properly for use in a hazardous area. The result of pressure piling can lead to a catastrophic event.

It’s important to understand what pressure piling is, what causes it, and how to prevent it.

Electrical devices need to be used in hazardous locations. These devices can become sources of ignition – they generate heat and in some cases arcs or sparks under normal operating or fault conditions. When an explosive gas makes contact with a source of ignition, an explosion can result. One effective way to control or contain such an explosion in hazardous areas is to place the electrical components containing hot surfaces or arcs and sparks inside an explosion proof enclosure.

Unless that enclosure is designed and installed correctly, pressure piling can take place, making the explosion worse.

Pressure is one of the expected outcomes whenever there is an explosion. When there’s an explosion inside an enclosure, pressure rises inside it and enclosures must be designed to withstand such pressure.

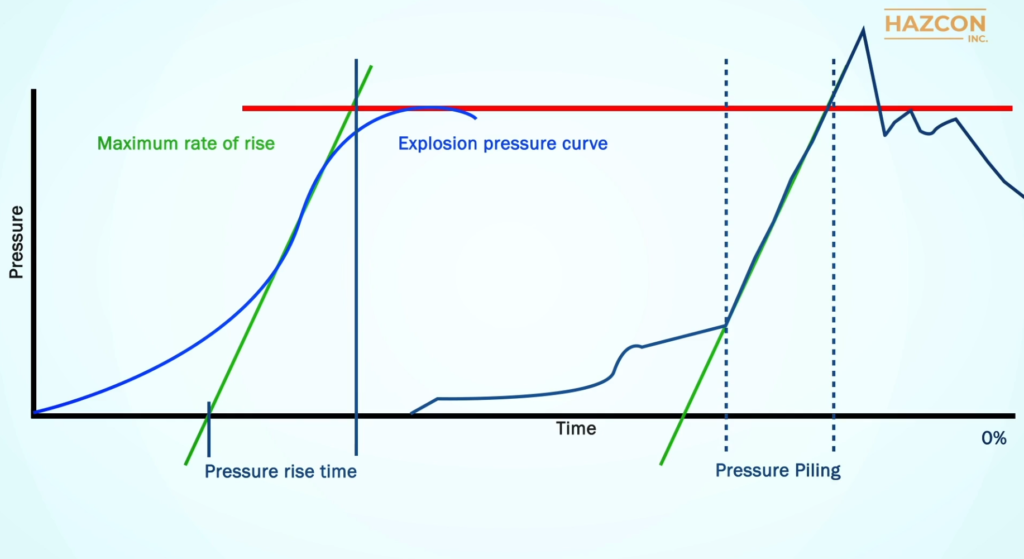

This pressure rise can be predicted, and its rise can be plotted on a graph such as this.

This graph illustrates three important characteristics related to the pressure:

- The time it takes in milli seconds for the maximum pressure, called the peak pressure, to be generated, shown in the horizontal axis

- The amount of pressure generated shown in the vertical axis

- And the pressure curve, a realistic portrayal of the rise in pressure and subsequent decline

Pressure piling changes the dynamic. The pressure curve becomes an irregularly shaped wave that illustrates the cascading effect of pressure piling – the multiple explosions that take place.

Pressure piling involves, as the name implies, the build-up of pressure, which can be higher than the expected peak pressure. There is presumption of pressure piling when the pressure rise time is less than 5 milliseconds.

Perhaps the best way to explain pressure piling is to look at three examples of it.

In our first example, the design of an explosion proof enclosure with two or more compartments allows unburned gas to collect in a particular space within the enclosure. The unburned gas in this space becomes compressed and therefore highly pressurized before being ignited. This pressure piling effect will lead to a higher explosion pressure.

In the second example, pressure builds up when an enclosure includes a component such as a circuit board, under which gas may collect. The gas present under the circuit board is, by design, compressed and could be ignited to generate a higher pressure.

Our third example involves two vessels or enclosures that are connected by a conduit or are nested together. If flame is allowed to exit one enclosure and travel down a conduit, for example, the unburned gas will be pushed ahead and will be highly compressed. Unburned gas ahead of the flame can get so hot that it reaches its auto-ignition temperature. This can actually cause an explosion within the conduit itself or generate a higher pressure inside the second enclosure and result in a disaster.

We are sure that you would never want to experience the result of this phenomenon. It is therefore important to understand it.

Now let’s review quickly how we can prevent pressure piling.

- Prevent unburned gas from collecting within an enclosure. This should be considered in the design of the enclosure

- Use stopping plugs or sealing material to seal off one enclosure from another and to seal off the conduit system

In summary, we should remember that pressure piling results when gases become highly pressurized through compression and when unburned gas pushed into a cavity becomes highly pressurized before being ignited. As a result, pressure piling leads to pressure that is higher than the expected peak pressure as a result of an explosion. Given such increased pressure, enclosures and piping systems might be unable to withstand the impact of an explosion.

A careful design and proper installation such as use of sealing between two enclosures are required to prevent pressure piling.

We hope you enjoyed this presentation. If you still have any questions, please ask the Hazcon team.

Request a Consultation

Complete the form below to get started.