Intrinsically Safe Systems

We provide engineering evaluations on intrinsically safe and non-incendive installations in hazardous areas.

Descriptive System Document – Intrinsic Safety (I.S.)

In order to operate safely in a hazardous environment, low voltage equipment such as sensors and instruments are typically protected using the intrinsic safety (I.S.) protection technique.

Intrinsic safety is an inexpensive and flexible protection method, based on limiting the energy in the hazardous area. The effectiveness of intrinsic safety relies on the fact that the electrical and thermal energy available for ignition is kept at a level below that which may cause ignition.

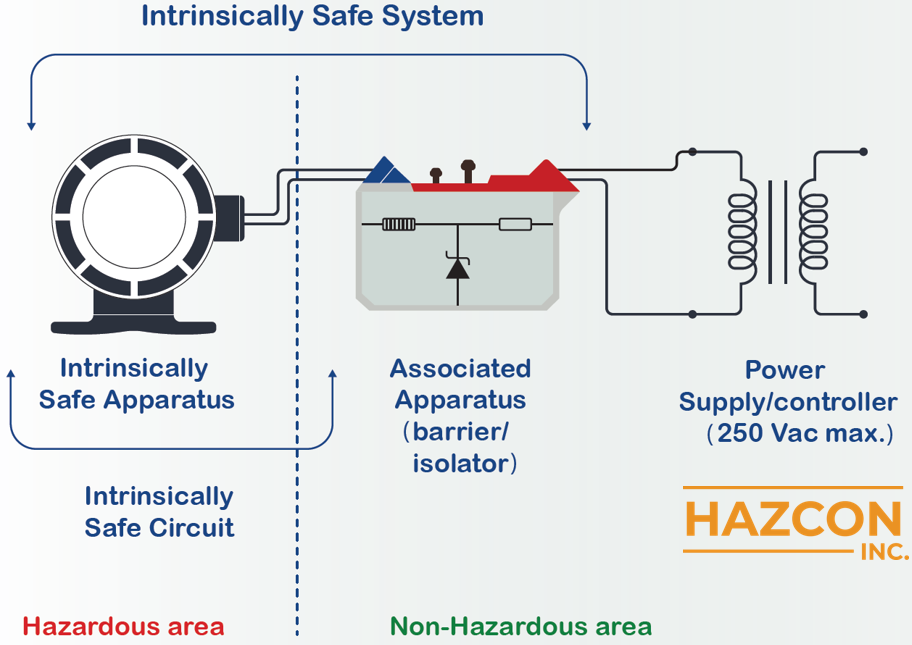

Intrinsic safety (I.S.) operates as a system concept, with each I.S. assembly comprising four main sections as defined below:

- An intrinsically safe field device (referred to as the I.S. device) situated within a hazardous area.

- A safety barrier (also termed as the associated apparatus), functioning as an energy-limiting device, typically positioned in a non-hazardous area. Alternatively, it may be located within a hazardous area, provided that additional protection techniques are implemented.

- Intrinsically safe circuit(s) originating from the I.S. side of the safety barrier and extending to the hazardous side. This encompasses the wiring connections between the safety barrier and the intrinsically safe field device.

- Intrinsically safe system, commencing from the non-IS side of the safety barrier, which is linked to power supply or control circuits, extending up to the entire circuit encompassing the I.S. device within the hazardous area.

It’s important to remember that each intrinsically safe device and safety barrier must possess its own certification. It's crucial to understand that a safety barrier cannot be utilized to guarantee the safety of an uncertified device within a hazardous area.

It's essential that these circuits are meticulously designed, installed, and maintained to ensure safe operation throughout their lifespan. Should a circuit become compromised or damaged during its operation, it could potentially serve as an undetected ignition source.

Hence, before choosing intrinsically safe and non-incendive field wiring circuit designs, designers must be aware that their responsibility extends beyond the design of the circuits.

A record of compliance that includes calculations that verify the permissible energy in the circuit is a mandatory requirement. It must be created, made available, updated if/when the system is modified, and referenced.

“Descriptive system document” is the name given to such a record. It specifies the electrical parameters of the system’s components (including the interconnecting wiring), as well as the system itself, in a given application, and includes calculations that verify compliance with relevant Standards and Codes (such as NFPA, CEC, and IEC). The descriptive system document (DSD) proves that the safety barrier is compatible with the I.S. device in terms of voltage, current, power, capacitance, and inductance values. Created at the system design stage, the DSD is instructive during system installation, maintenance and modification. It must be easily accessed for reference on an ongoing basis.

In order to illustrate compliance of an I.S. system, descriptive system documents must:

- list the devices and cabling in each I.S. circuit

- include calculations that verify the permissible energy in the circuit, including the summation of energy if several devices are included

- include details about the earthing and bonding points of the I.S. system

- identify gas groups, protection level and temperature classifications, cable requirements and parameters)

- include relevant drawings and reports (e.g., to identify what devices are located in the non-hazardous area or the hazardous area and how they are connected)

- be signed and dated by a qualified person

- be given a unique ID number

The DSD needs to be carefully crafted and updated to ensure that all relevant information for a particular installation is readily accessible.

In Canada, the CEC (Canadian Electrical Code) mandates that the DSD (Descriptive System Document) be prepared by a registered professional engineer operating under a permit to practice. Additionally, any relevant drawings and reports included must also be signed and stamped by a PE member. In the US, and for ATEX and IECEx installations, the descriptive system document must be crafted by an experienced and competent I.S. system designer.

I.S. systems vary in complexity, ranging from simple setups to more intricate configurations. For instance, some I.S. systems feature multiple intrinsic safety circuits, such as a dual-channel safety barrier providing two I.S. circuits for a single I.S. device. Alternatively, within a specific installation, several intrinsically safe systems may be grouped together (e.g. (e.g., a safety barrier panel containing multiple safety barriers limiting energy to the I.S. devices located in the skid or process equipment assembly). Consequently, descriptive system documents can range from straightforward to complex.

Furthermore, what initially appears as a simple system may undergo modifications over time. This necessitates the revision of the original descriptive system document to ensure ongoing compliance.

How Hazcon Can Help

We have 15 years’ experience in protection techniques for hazardous locations, as well as in design, certification and installation of intrinsic safety at the component or system level. We can provide a comprehensive assessment and evaluation from I.S. product design to system verification for both Division and Zone systems.

Our engineering services for your intrinsically safe installations in hazardous areas include:

- Interpreting current, applicable Codes and Standards to ensure compliance at the design, installation, and maintenance stages

- Providing fault assessments, spark assessments, thermal assessments and supporting calculations for field wiring installations

- Preparation of engineering documents:

- SEALED & STAMPED descriptive system documents required for the installation and verification of an intrinsically safe system

- control drawings and intrinsically safe block diagrams with details of electrical parameters governing interconnections of the associated apparatus and intrinsically safe devices

- Evaluation of:

- entity parameters of intrinsic safety barriers and intrinsically safe field devices for a safe installation

- electrical parameters for interconnecting wiring

- grounding and bonding requirements of safety barriers and I.S. devices in hazardous areas

- Verification of:

- temperature class (T-code), gas or dust groups, the equipment protection level (EPL)

- conditions for safe use of certified devices

Request a Consultation

Complete the form below to get started.